Where are they now: PolyNovo

May 7, 2025

A Basement Start‑up with a CSIRO Backing

What began as a small Melbourne spin‑out has quietly redrawn the map of burn care across the globe. In an age of billion‑dollar health‑tech hype cycles, PolyNovo stands out precisely because its story is so unassuming: a handful of polymer chemists and a burns surgeon determined to build a better skin substitute, working in a converted warehouse by the docks in Victoria. Twenty years later their NovoSorb® platform is saving limbs, salvaging lives and reminding the world that breakthrough science can still wear an Australian accent.

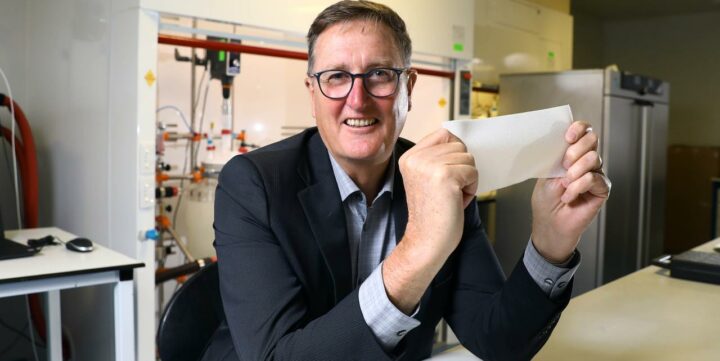

PolyNovo was born in 2004 when CSIRO researchers Thilak Gunatillake, Raju Adhikari and Roshan Mayadunne spun their biodegradable polyurethane know‑how into a joint venture with Xceed Biotechnology. They called the material NovoSorb, and within months—burns specialist Professor John Greenwood was trialling early foams in animal studies, hoping to “temporise” a wound long enough for the body to rebuild its own dermis.

That marriage of blue‑sky polymer science and blunt surgical need forged a culture that has never really left PolyNovo. When the business changed hands—first through Metabolic Pharmaceuticals and then a 2014 relisting under the PolyNovo name—it kept the humility of its lab‑coat roots. What mattered was getting patients through the theatre doors faster, not ringing the ASX bell.

Healing. Redefined.

PolyNovo’s identity bares a simple two‑word vision: Healing. Redefined. The supporting mission statement is deliberately ambitious—“to innovate and bring disruptive technologies to market by partnering with the best minds to improve patient outcomes and re‑imagine the standard of care.”

Anyone who has witnessed a full‑thickness burn graft slide off necrotic tissue understands why those words matter. Traditional split‑skin grafts ask the body to accept a fragile epidermal layer before a healthy dermis has formed; failure rates are high, operations are repeated, and scarring is disfiguring. NovoSorb BTM flips that sequence. Its porous foam invites blood vessels and fibroblasts to colonise the defect first, building a sturdy neo‑dermis; only then is a thin graft applied. In practice that means fewer returns to theatre, better graft “take,” and limbs that bend rather than contract.

Milestones that tell a Decade‑Long Story of Credibility

NovoSorb’s promise would be purely academic without the regulatory, clinical, and commercial validation PolyNovo has amassed over the past decade. The journey began in 2013 with the first human implantation of NovoSorb BTM in Adelaide. Two years later, the U.S. FDA granted 510(k) clearance, and within weeks PolyNovo secured an initial US$11 million BARDA contract—ultimately extended to US$36 million—to fund a 150‑patient pivotal burn trial. In 2018 the Therapeutic Goods Administration conferred Class III approval, prompting nationwide adoption across every major Australian burns unit, and the following year CE‑Mark certification opened the door to the European Union.

By 2022 the portfolio expanded when the FDA cleared NovoSorb MTX, a single‑layer scaffold aimed at chronic and smaller wounds. Momentum culminated in 2023–24: more than 50,000 patients in 41 countries had been treated, and PolyNovo emerged as the category leader in burn care across multiple regions. Each milestone signifies more than bureaucratic checkboxing; it traces the steady rise of clinician confidence. When NovoSorb BTM was deployed to treat victims of New Zealand’s White Island volcano disaster, surgeons reported outcomes once thought impossible—hands saved, faces reconstructed, and intensive‑care stays dramatically shortened. Those results now drive uptake in trauma, necrotising fasciitis, and limb‑salvage orthopaedics worldwide.

One criticism often seen with single‑product med‑techs is strategic myopia. PolyNovo has answered with pipeline breadth. The same foam‑and‑film chemistry behind BTM has already yielded NovoSorb MTX for diabetic foot ulcers, and is inching toward Syntrel®, a fully bio-absorbable hernia mesh whose film layer supplies tensile strength while the foam invites native tissue in‑growth. It’s safe to say that the extent of clinical applications this biotechnology offers are yet to be fully realised.

Company Progress

Under the bonnet, the company has quietly built manufacturing muscle to match its R&D pipeline: ultrasonic welding lines for mesh, extrusion capacity for thin polymer films, and a quality‑control system that has already satisfied FDA, TGA and EMA auditors. That infrastructure can be repurposed for orthopaedic spacers, breast reconstruction slings—even drug‑eluting implants that marry polymer resorption with controlled therapeutic release.

Financially, PolyNovo’s FY24 report shows revenue leaping 46 per cent and net profit swinging from a $4.9 million loss to a $5.3 million profit. Importantly, that growth is not a one‑market wonder: the U.S. remains the engine, but Europe, the UK/Ireland cluster, and Asia‑Pacific distributors are all double‑digit contributors. By absorbing its own cost of goods inside Australia, PolyNovo insulates margins and keeps high‑value manufacturing jobs onshore—a refreshing twist in an era when many biomedical licences are off‑shored at the first whiff of scale.

Equally telling is the absence of a mega‑merger narrative. Former CEO Paul Brennan repeatedly rebuffed suggestions that PolyNovo was priming itself for acquisition; the current board echoes that independence. The unspoken message is clear: Australia can nurture and keep a world‑class med‑tech champion if it chooses to.

Looking forward: Why PolyNovo Matters

PolyNovo’s latest vision statement talks of treating “millions more” patients. That is not hyperbole. Severe burns disproportionately affect low‑ and middle‑income nations, where open‑fire cooking, industrial accidents and limited surgical capacity converge. NovoSorb’s relatively simple two‑stage protocol—place the scaffold, wait, graft—could be transformative in those settings. The company has already entered India’s government procurement portal and is courting regulatory approvals in China, South Korea and Brazil.

On the science front, the next five years will test whether NovoSorb can transcend soft‑tissue reconstruction. Drug‑loaded scaffolds for chronic osteomyelitis, islet‑cell seeded foams for diabetes, bio‑printed composites for cartilage—each is technically plausible. But the road from concept to clinic is littered with regulatory landmines and capital‑raising fatigue. PolyNovo will have to balance its urge to invent with the discipline that has served it so well to date: pick the indications where polymer physics genuinely rewrites biology.

PolyNovo is the most important Australian contribution to wound care since spray‑on skin. It has rescued burn surgeons from a therapeutic cul‑de‑sac, replaced hospital rounds of despair with rounds of possibility, and done so while staying commercially self‑reliant. The next chapter will be written in new indications, new continents and new demands. But it will always trace back to that modest Melbourne lab where polymer foam began to redefine healing for the world.